4D Printing Technology Makes Use of Commercial 3D Printers

|

| 4D Printing |

A device or object that can change from a 1D strand into a pre-programmed 3D shape, from a 2D surface into a pre-programmed 3D shape, or that can morph between multiple dimensions is said to be printed in four dimensions using a single substance or a combination of materials. Electrochemically, by programming different sensitivity to, for example, swelling into various parts of the designed geometry, and by applying various stimuli, such as heating, light, or swelling in a liquid, these transformations are made possible. These methods promise new ways to embed programmability and straightforward decision making into non-electronic based materials while providing adaptability and dynamic response for structures and systems of all sizes.

The global 4D Printing Market was valued at US$ 82.6 Mn in 2020 and is expected to reach US$ 625.6 Mn by 2028 at a CAGR of 29.4% between 2021 and 2028.

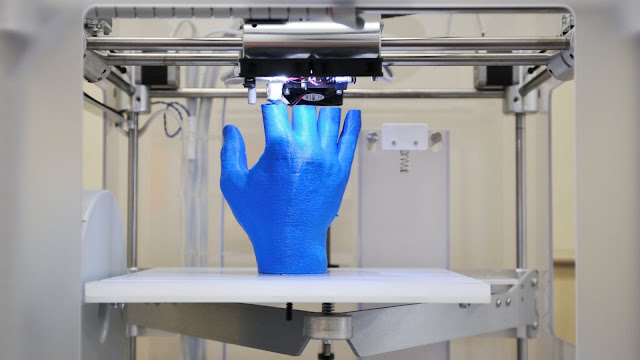

Layer by layer, 3D printing, commonly referred to as "Additive Manufacturing," creates tangible products from digital blueprints. This technology is the foundation of 4D printing. With one significant exception: It makes use of unique materials and intricate designs that are "programmed" to cause your 3D print to take on a different shape. As a result, 4D printing is essentially an upgrade to 3D printing that uses special materials to print objects that can change shape after they are produced. Water, heat, wind, and other sources of energy could act as a catalyst.

Commercial 3D printers, including Polyjet 3D printers, are used in 4D printing technologies. A "smart substance," which can be a hydrogel or a shape-memory polymer, is the input. Smart materials are distinguished from typical 3D printing materials and given the features of shape change thanks to their thermomechanical capabilities and other material properties. On the other hand, stiffness is a trait of items produced using 3D printing technology. This indicates that after being printed, 3D objects will maintain their 3D shape. 4D, developed in collaboration with the California-based company Carbon, has been dubbed the world's first pair of performance shoes manufactured with light and oxygen using digital light synthesis.

.jpg)

Comments

Post a Comment