Motorized Control Valves Are an Important Part of Many Industrial Operations

Motorized control valves are an essential component in many industrial processes and are used to regulate the flow of fluid or gas in pipelines. These valves are designed to control the flow of fluids or gases based on input signals received from controllers, sensors, or other systems. With the ability to control the flow, these valves play a crucial role in ensuring safety, accuracy, and efficiency in various industrial applications.

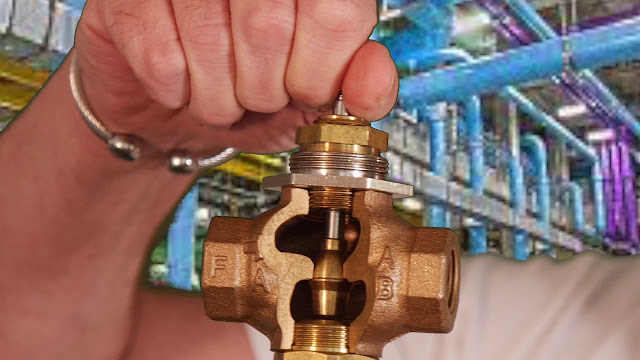

The basic principle of Motorized control valves is that they have an actuator that is powered by an electric motor, which opens and closes the valve in response to an input signal. The actuator is connected to the valve body by a stem, which translates the rotary motion of the motor into linear movement of the valve. The valve body, in turn, contains the flow control element, which regulates the flow of fluid or gas. The control element can be in the form of a globe, ball, or butterfly, depending on the application.

According to Coherent Market Insights the Motorized Control Valves Market Global Industry Insights, Trends, Outlook, and Opportunity Analysis, 2022-2028.

One of the key advantages of Motorized control valves is that they can be remotely controlled, which makes them ideal for use in hazardous or hard-to-reach areas. This makes them much more flexible and versatile than manual valves, which require manual intervention to operate. Additionally, the electric motor can be controlled precisely, which makes it possible to control the flow of fluid or gas with a high degree of accuracy.

Another advantage of Motorized control valve is that they can be used to control the flow of fluids or gases that are dangerous or corrosive. For example, in the chemical industry, Motorized control valve are commonly used to regulate the flow of toxic or corrosive fluids, which would be unsafe for human operators to handle. In this case, the electric motor can be operated from a safe distance, making it possible to control the flow of fluid or gas with minimal risk.

There are several different types of Motorized control valves available, each with their own unique features and advantages. One of the most common types of Motorized control valve is the globe valve, which has a cylindrical body and a flow control element that is usually a disk that moves linearly along the axis of the body. Globe valves are commonly used in applications where the fluid or gas flow needs to be regulated precisely, such as in chemical and petrochemical processes.

Comments

Post a Comment