Revolutionizing Tire Performance: Unleashing the Power of Advanced Tire Chord and Tire Fabrics

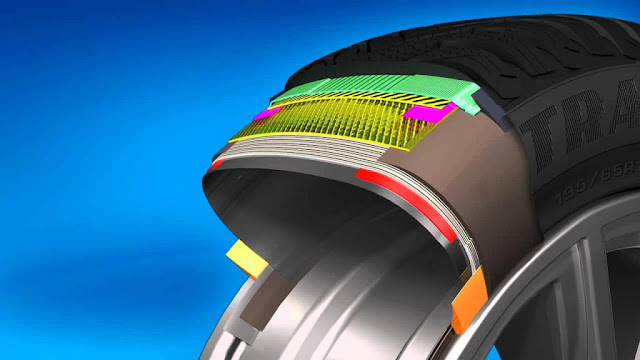

In the ever-evolving world of tire technology, advancements in Tire Chord and Tire Fabrics have emerged as key drivers of revolutionizing tire performance. The integration of advanced chords and fabrics has unleashed a new era of capabilities, pushing the boundaries of safety, durability, and overall performance. Tire cords, which serve as the reinforcement within tires, have witnessed significant advancements in recent years. Traditional steel cords have been joined by innovative materials like aramid fibers, polyester, and nylon. These high-strength materials offer exceptional tensile strength, enabling tires to withstand extreme forces encountered during driving. The use of advanced tire cords not only enhances the structural integrity of the tire but also improves its resistance to punctures, cuts, and impacts.

Tire Chord and Tire Fabrics, known for their exceptional strength-to-weight ratio, have gained particular attention in the tire industry. With properties surpassing that of traditional materials, aramid tire cords provide enhanced strength and robustness while maintaining a lightweight profile. This combination contributes to improved fuel efficiency and reduced rolling resistance, resulting in lower energy consumption and reduced carbon emissions. Moreover, advanced tire cords have a direct impact on tire longevity. Their increased durability and resistance to wear and tear allow tires to withstand the rigors of daily use for extended periods. This translates into longer-lasting tires, reducing the frequency of replacements and contributing to sustainability efforts.

The Tire Cord and Tire Fabrics Market is estimated to surpass US$ 7,386.7 million by 2027, exhibiting a CAGR of 5.5% between 2020 and 2027.

While tire cords provide the foundational strength, tire fabrics play a crucial role in enhancing tire performance. Tire fabrics act as a flexible layer between the cords and the tire's external rubber compound, balancing strength and flexibility for optimal performance. Traditionally, polyester and nylon fabrics have been widely used in tire manufacturing. These materials offer excellent flexibility, ensuring smooth and comfortable rides while effectively absorbing shocks and vibrations. Additionally, they provide reinforcement to the tire structure, enhancing its load-bearing capacity and improving overall stability.

The development of innovative Tire Chord and Tire Fabrics has further elevated tire performance to new heights. Manufacturers now utilize advanced weaving techniques and proprietary materials to create fabrics with tailored characteristics. For instance, the incorporation of high-modulus fibers in tire fabrics enhances the stiffness of the tire sidewalls, resulting in improved handling and cornering capabilities. This ensures better control and responsiveness, especially in demanding driving conditions. Furthermore, tire fabrics have become increasingly versatile in addressing specific performance requirements. For instance, the development of silica-infused fabrics has revolutionized wet traction performance. Silica enhances the tire's grip on wet surfaces, reducing braking distances and improving overall safety.

.jpg)

Comments

Post a Comment