Aircraft Actuators: The Unsung Heroes That Make Flight Possible

|

| Aircraft Actuators |

Aircraft require various mechanical systems and components

to function properly and safely. While many of these systems operate behind the

scenes, they play a critical role in flight. One such component that is

integral to aircraft operation but often goes unnoticed are actuators.

Actuators are electromechanical devices that help convert electrical or

hydraulic signals into physical movement. On aircraft, they are utilized

throughout to move flight control surfaces, landing gear, and other mechanisms

that are essential for take-off, landing, and safe flight.

Types of Actuators Used on Aircraft

There are a few main types of actuators commonly found on modern aircraft:

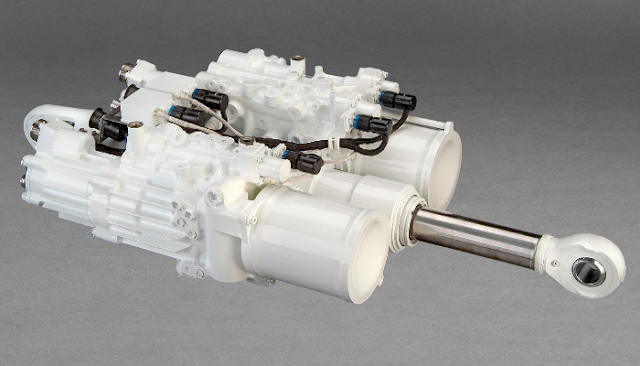

Hydraulic Actuators: Hydraulic actuators are among the most prevalent actuator

types used on commercial and military aircraft. They utilize hydraulic

pressures to generate movement which allows for strong, precise movements of

heavy components. Hydraulic actuators are frequently employed to control flight

surfaces like ailerons, elevators, and rudders. Their reliability and power

capabilities make them well-suited for critical flight control functions.

Electromechanical Actuators: Also known as electric Actuators, electromechanical actuators

generate movement through electric motors rather than hydraulics. They are

generally lighter and require less maintenance than hydraulic actuators. Common

applications include moving high-lift devices, landing gear, and other

secondary flight control systems. Some newer aircraft are utilizing

electromechanical actuators more extensively as electric flight increasingly

takes hold.

Pneumatic Actuators: While less common than hydraulic or electromechanical

types, some aircraft still use pneumatic actuators which are driven by

compressed air. Applications may include operating cargo doors or auxiliary

flight control surfaces. Pneumatic actuators tend to be simpler and lighter

than hydraulic equivalents.

Rod End Actuators: Also called push-pull actuators, rod end actuators function

through mechanical linkages rather than hydraulic/electric power. They are

generally found on small aircraft, ultralights, and homebuilts to operate

flight controls in a basic manner.

Key Functions of Actuators in Aircraft Operation

Now that we understand the different actuator types, we will explore some of

their most critical functions that enable safe aircraft operation:

Flight Control: As mentioned, hydraulic actuators almost universally power

primary flight control surfaces like ailerons, elevators, rudders, and flaps.

They provide the precise, forceful movements needed to direct the aircraft

during all phases of flight.

Landing Gear Operation: Actuators hydraulically or electrically retract and

extend aircraft landing gear. This includes everything from simple strut gear

to complex tricycle systems. Proper landing gear operation is vital for

takeoffs and landings.

High Lift Device Control: High lift devices such as slats and flaps are

actuated to optimize wing lift during takeoff and landing via approach

maneuvers. Actuators position these flight surfaces for each phase of flight.

Weapon Bay Doors: Military aircraft often rely on actuators to rapidly open and

close internal weapon bay doors to deploy ordnance payloads at the correct

times.

Cargo Door Operation: On commercial and military cargo planes, actuators power

internal and external cargo doors to load and unload freight.

Auxiliary Functions: Additional uses include operating shades, hatches, probes,

antennas, and other movable components as needed.

Significant Role in Aircraft Safety

As the above functions demonstrate, actuators are integral to practically every

major system involved in getting aircraft airborne and back on the ground again

in one piece. Their reliable, precise operation is absolutely critical for

safety. Any actuator failure could potentially lead to disastrous control issues,

inability to takeoff or land, cargo/payload instability, and more. Therefore,

actuators are designed with redundancies, undergo rigorous testing, and require

frequent maintenance inspections. While generally operating out of sight,

actuators undeniably play an important unsung role in the dependable operation

of all aircraft types. With new technologies advancing actuator capabilities

further, their contributions to aviation safety will surely continue.

For More Details On The Report, Read: https://www.trendingwebwire.com/aircraft-actuators-the-unsung-heroes-behind-aircraft-control/

.jpg)

Comments

Post a Comment